MES System

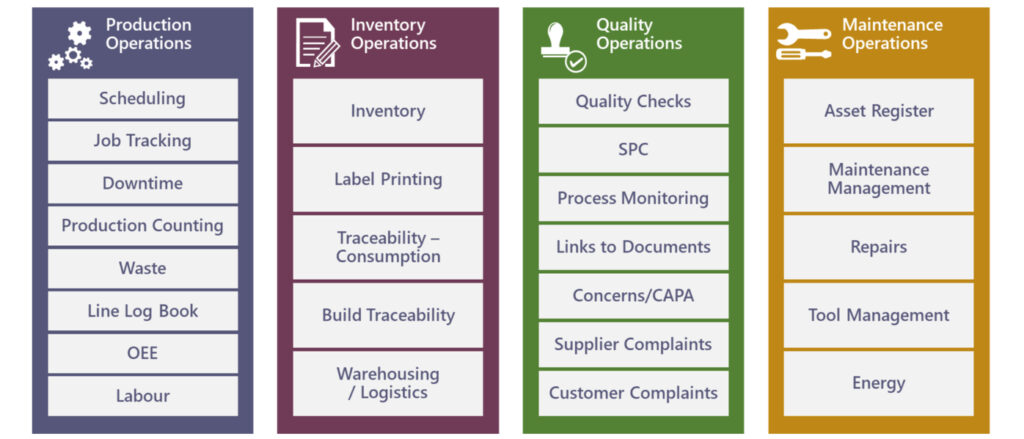

Manufacturing Execution Systems (MES) is a specialist class of production-oriented software that manages, monitors and synchronizes the execution of real-time, physical processes involved in transforming raw materials into intermediate and/or finished goods. These systems coordinate this execution of work orders with production scheduling and enterprise-level systems like ERP and product life cycle management (PLM). MES applications also provide feedback on process performance, and support component and material-level traceability, genealogy and integration with process history, where required.

Manufacturing execution systems (MES) traditionally link ERP (and other business systems) and data flow control and monitoring on the plant floor (operational plant-control systems). How manufacturing execution systems have been and are evolving in the context of smart manufacturing, industrial transformation and end-to-end manufacturing operations management.