Factory Automation and Machine Connectivity

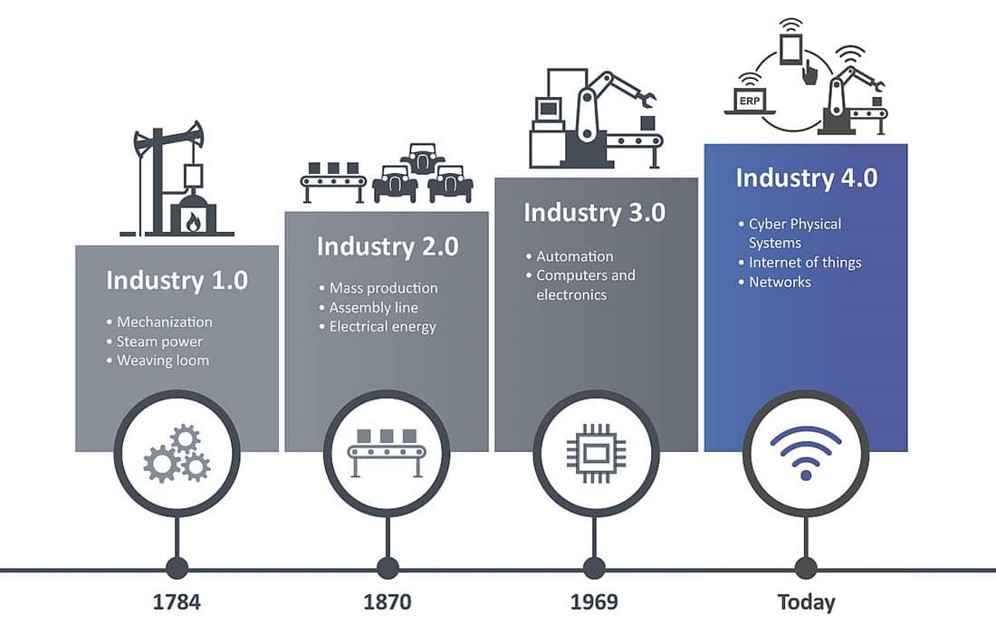

We’re in the midst of a significant transformation regarding the way we produce products thanks to the digitization of manufacturing. This transition is so compelling that it is being called Industry 4.0 to represent the fourth revolution that has occurred in manufacturing. From the first industrial revolution (mechanization through water and steam power) to the mass production and assembly lines using electricity in the second, the fourth industrial revolution will take what was started in the third with the adoption of computers and automation and enhance it with smart and autonomous systems fueled by data and machine learning.

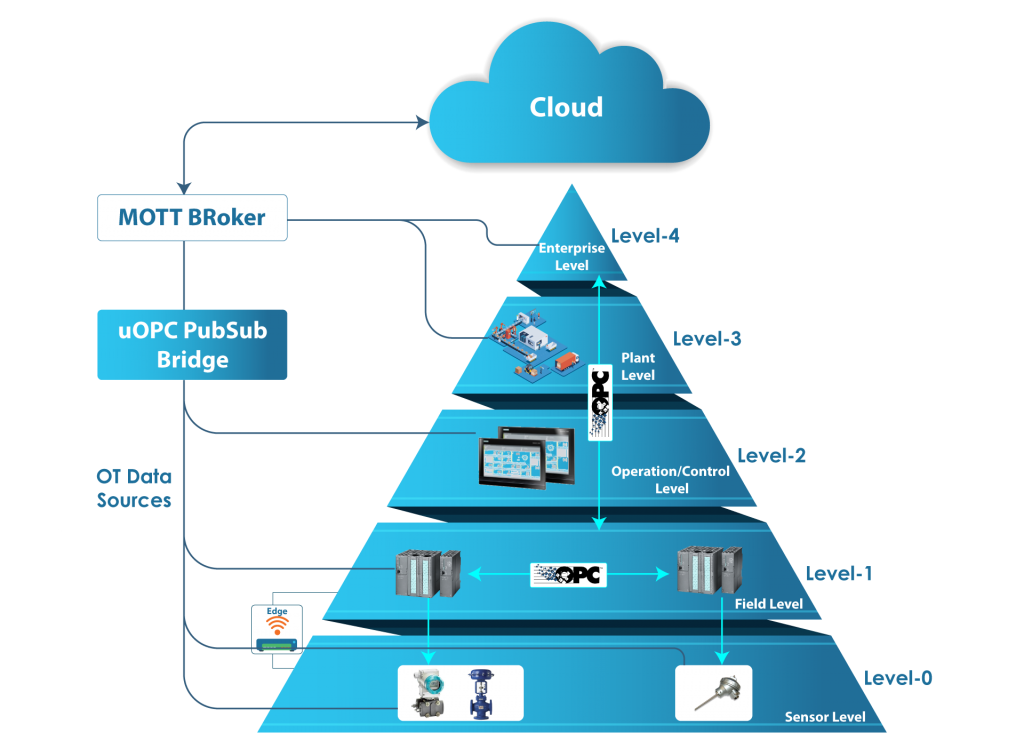

With an integrated System the Production Automation System is linked to the Business & information System over one common Communication Network. With such integrated system in place, the following information systems can share information and data with the actual manufacturing process:

* Inventory / Stock

* Lab / QC

* Production Scheduling

* Maintenance

* Labor Cost Reduction

* Paper Reduction

* Higher Quality Control / Standardization

* Better Record Keeping

* Decrease Maintenance Costs

* Data Exchange between higher level systems

* Industrial Internet of Things (IIoT) for machine connectivity

Maximize your factory's potential with our expert automation, machine connectivity and IT/OT integration services. Our world-class solutions will optimize your processes, increase efficiency, and deliver rapid ROI.

Revolutionize Your Factory with Automation and IT/OT Integrations

Integrate your IT and OT systems for end-to-end visibility and control. Our integration services enable seamless data exchange and facilitate decision-making in real-time.

Our Iintegration solutions feature comprehensive data management software, enabling automated data processing and analysis across both your IT and OT systems.

Our integration services offer real-time visibility and control over your factory processes, enabling swift, decisive, and data-driven decision-making.

Our connectivity solutions offer seamless integration of IT and OT networks, allowing for secure data exchange and communication across your entire enterprise.

Data Management

Real-time Visibility

Connectivity

The ideal OPC UA server for Industry 4.0 systems

Much More Than an Ordinary UPC UA Server

-

Connext© OPC UA software is a connectivity engine for every data acquisition, deployment and recording need in M2M, cloud, and IIoT deployments

It offers advanced tools that include Gateway, Historian, Alarms and Conditions, IIoT and Redundancy functions. Connext provides a data link allowing any field device to communicate with SCADA/Plant Analytics/ERP systems or to record information on any database or the cloud with IoT protocols.

Connext© means connectivity without limits across Industry 4.0 platforms and systems, with fulfillment of every data acquisition, publication and recording objective.

Advantages of using this product

Certified Data Server

Openness

Communication Protocols

Cost Reductions

Connext© supports OPC Foundation’s data and alarm specifications for servers.

Customize your protocols and expand on Connext’s© library of available drivers.

OPC UA Server supports automatic import and fast configuration of protocols.

Connext’s© modular license policy adjusts to the required number of tags.